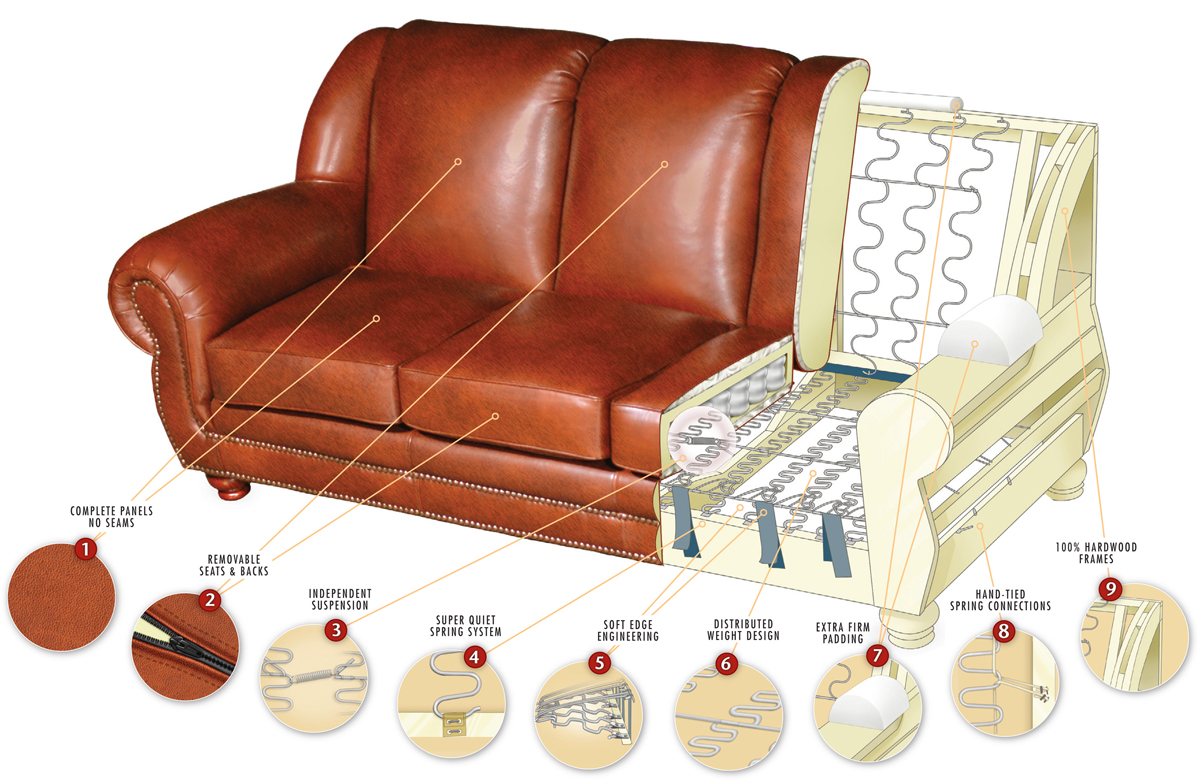

To warranty them like we do, you have to construct them like we do. Leather Creations is proud to openly talk about what is commonly referred to as the blind item. Everything that goes on under the hood is going to ensure that your foundation will last as long as the leather is designed to last.

1- Complete Panels - No Seams Showing the Highlight Every Full Top Grain Leather

COMPLETE PANELS – We use superior qualityhides that have fewer beauty marks. Just like a fine solitaire diamond the higher quality the larger the diamond ring can be. In much the same way, we show off the quality of our hides by having full panels wherever we can. Furthermore, this reduces stress seams in the seats and backs reducing the likelihood that a seam splits. The end result is it looks much better and it’s much stronger.

2 - Removable Seats & Backs to Refill, Replace & Rotate

REMOVABLE SEATS & BACKS – Simply put, making your seat cushions and back pillows removable takes 1/3 more labor and 1/3 more materials. We do this because we know the material inside the leather covers will not last as long as the leather itself. This gives you the ability to rotate your seats and backs as well as refill them to keep them looking and feeling new throughout their usable life. The same way your tires are replaceable, your seat cushions and back pillows can be replaced with firmer or softer material to always ensure you are comfortable.

3 - Independent Suspension So You Don't Get Sucked Into Another Seat

INDEPENDENT SUSPENSION – You can build furniture faster then we do, but you can’t build it any better. Our independent seating is one of many extras that our spring system features. It’s designed so that your seating comfort is not determined by the weight of the person sitting next to you. If this step is omitted and someone heavier sits next to you, you will feel a black hole sucking you into the seat next to you.

4 - Super Quiet Spring System Reducing Creaks & Squeaks

SUPER QUIET SPRING SYSTEM – Our springs are attached by 2 nails directly to 1” hardwood frames. The clips we use are lined with nylon material to keep the springs from squeaking throughout the years. Our entire spring system is then covered in a resilient noise-dampening wrap to ensure a smooth and quiet ride.

5 - Soft Edge Engineering Your Knees Will Appreciate

SOFT EDGE ENGINEERING – 50 years ago, every sofa was built this way. Only the best manufacturers still offer this option but it’s a standard with every stationary piece we make. It’s designed to give the seat cushion a buffer that works with the cushion as opposed to against it. The result is longer lasting seat cushions. This extra spring also supports your knees and improves the comfort level of our furniture. Finally, the angled effect acts as a wedge keeping your seat cushions in place and helps keep them from sliding out.

6 - Distributed Weight Design For Even Seating Everywhere

DISTRIBUTED WEIGHT DESIGN – We use a double row of coated tie wires to connect all springs together located under your seat. This is designed to dispurse the weight evenly over all springs causing a more comfortable ride as well as creating a bigger foundation to sit on. This increases the lofe expectency of your spring system and is part of the reason we give you a life time warranty on the entire spring system.

7 - Extra Firm Padding Your Elbows and Back Will Love

EXTRA FIRM PADDING – In most cases, we use 3 or 4 layers of padding in all areas. This gives you a better feel for your elbows as you rest your arms. Our material is designed for the utmost comfort and durability. This also gives your leather a foundation that supports the natural drape of the leather. Without enough padding, your furniture will not be as comfortable and will eventually show unnatural lines created by the pressure of the wood frame below.

8 - Hand Tied Spring Connections So There Is No Gap Near the Arm

HAND TIED SPRING CONNECTIONS – Another critical component of our spring system. Over years, the pressure of sitting on a spring will cause it to pull away and bend towards the middle of the sofa. This creates an uneven spring system and a large gap from the inside edge of the arm to the first spring. You have probably felt a hole near the arm in furniture before. This is a sure sign that a shortcut was taken. We hand tie the springs to the frame using nylon Ludlow twine designed to never allow this to occur.

9 - 100% Hardwood Frames That Are 1 Inch Thick For a Lifetime Of Usage

100% HARDWOOD FRAMES – Make that 100% 1” thick kiln dried hardwood frames. Our competitors use 3/4” or less. This is 25% – 50% less structural strength. We use the finest grade 1 hardwoods that have fewer knots and a tighter grain. These woods can be Oak, Maple, or Poplar. We also use 100% engineered hardwood for form-fitting and larger pieces that can no longer be harvested from old growth trees.